Industrial Supplies in Malaysia: Comprehensive Guide for Businesses

11/03/2025What is a Conveyor System? Overview, Benefits, and Applications

Did you know conveyor systems can cut material handling costs by up to 50%? In Malaysia’s booming industrial sector, knowing about conveyor technology is key. A conveyor system moves materials efficiently from one place to another. It’s vital in industries like manufacturing, warehousing, and food processing.

These systems are not just versatile but also boost productivity and safety. By making bulk material movement smoother, they help companies work better and save on labor costs.

Key Takeaways

- Conveyor systems are essential for efficient material handling in multiple industries.

- They can significantly reduce operational costs, improving the bottom line.

- Different types of conveyors are designed for various materials and industries.

- Incorporating conveyor technology enhances overall productivity and safety.

- These systems provide consistent and reliable transportation of goods.

Understanding Conveyor Systems

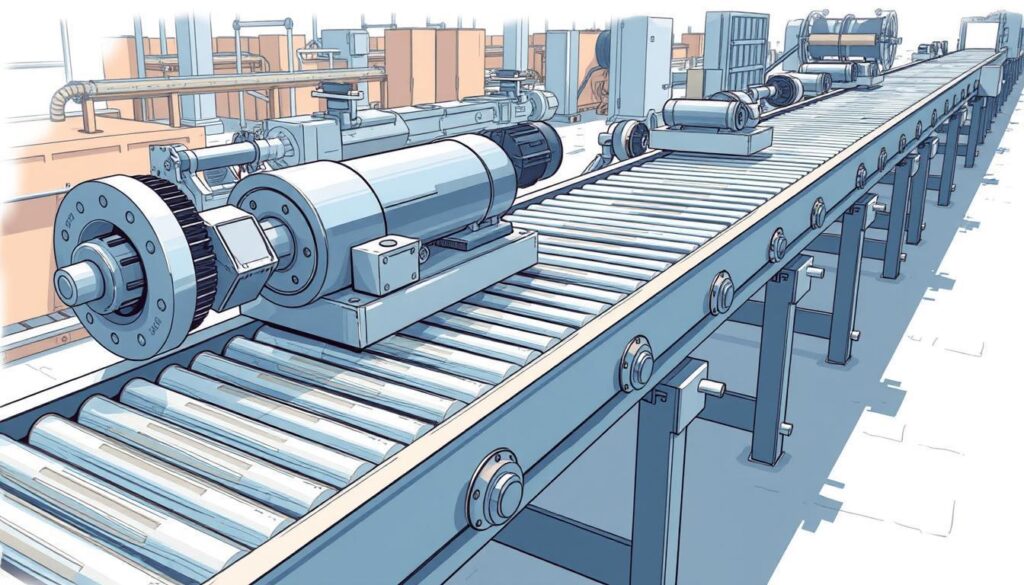

In the world of work, conveyor systems are key to making things run smoother and faster. They help move products or materials around, which is crucial for today’s material handling. Knowing what a conveyor system is and its types helps businesses pick the best one for them.

Definition of a Conveyor System

A conveyor system is a set of machines that move things from one place to another. It makes work easier and cuts down on manual tasks. These systems use belts, rollers, and more to move different kinds of materials, boosting work efficiency.

Types of Conveyor Systems

There are many kinds of conveyor systems in Malaysia, each for different needs. Below is a list of some common ones and what they’re good for:

| Type of Conveyor System | Applications | Load Capacity | Speed |

| Belt Conveyor | Transporting bulk materials, packages | Varies; typically moderate to high | Moderate |

| Roller Conveyor | Handling boxes and pallets | High | Fast |

| Modular Conveyor | Flexible and adjustable layouts | Moderate | Variable |

| Overhead Conveyor | Space-saving solutions, light materials | Moderate | Fast |

Choosing the right conveyor system depends on several things like how big the load is, how fast it needs to go, and what it’s carrying. Companies that handle materials can really improve their workflow by understanding the material handling system used. It helps them work more efficiently and smoothly.

Key Components of a Conveyor System

Knowing the main parts of a conveyor system is key to better performance and handling materials well. The main conveyor components that make up a successful system include conveyor belts, rollers, idlers, and drive mechanisms. Each part has its own role in making the conveyor system work smoothly.

Conveyor Belts

Conveyor belts are the heart of conveyor systems, moving goods from one place to another. They come in different materials, like rubber, PVC, and polyurethane. These materials vary in durability and resistance to wear.

The type of conveyor belt used greatly affects the system’s efficiency and how long it lasts.

Rollers and Idlers

Rollers and idlers support the belt, keeping it aligned and stable. They help reduce friction, making the belt move smoothly. This reduces wear on the belt.

The design of these parts is crucial for better system efficiency. It helps lower costs and boost productivity.

Drive Mechanisms

Drive mechanisms give the power needed to move the belts. They can be electric motors, hydraulic systems, or gear drives. Each has its own benefits for different needs.

Choosing the right drive mechanism is important. It affects the belt’s speed and force. Knowing this ensures the conveyor system works its best.

The Importance of Conveyor Technology

Conveyor technology keeps getting better, making big changes in many industries. It boosts productivity, safety, and how well things work. These updates help meet the needs of today’s fast-paced production world.

Advancements in Conveyor Design

New designs in conveyor systems bring many benefits. They meet the complex needs of making and moving products. Some key improvements include:

- Modular Components: Make it easy to change and grow systems.

- Advanced Materials: Make them last longer and cost less to keep up.

- Ergonomic Designs: Help workers stay safe and comfortable while working well.

These new designs make systems work better and are simpler to handle. They are key in today’s industrial world.

Incorporating Automation in Conveyor Systems

Adding automation to conveyor systems is a big change. It makes handling materials smoother by watching and adjusting in real time. The benefits of automated conveyor systems are:

- Increased Productivity: They work non-stop, with almost no breaks.

- Improved Accuracy: They cut down on mistakes, making products better.

- Flexibility: They can change with production needs, making things more efficient.

The move towards more automation solutions in Malaysia for conveyor tech is vital. It helps tackle the challenges of today’s making and moving products.

Benefits of Using a Conveyor System

More and more businesses are turning to conveyor systems to boost their productivity. These systems bring two main benefits: they make material handling more efficient and help cut costs. These advantages are key to improving operations in many industries.

Increased Efficiency in Material Handling

Conveyor systems make moving materials around a facility much faster. They cut down the time it takes to move products from one place to another. This means more products can be moved in less time.

By not needing people to move things manually, companies save a lot of time. Employees can then focus on tasks that are more important. This makes the workflow smoother and more efficient.

Cost Reduction and Labor Savings

Using conveyor systems can also save a lot of money. Companies spend less on labor because they don’t need as many people to move things. This also reduces the chance of injuries that can happen when people move things by hand.

With conveyor systems, companies can use their people for tasks that are more valuable. This makes the whole operation more effective. Investing in conveyor technology is a smart move for saving money in the long run.

Conveyor System Applications Across Industries

Conveyor systems are used in many industries. They help with different needs. Each field uses them to work better, faster, and safer.

Manufacturing and Assembly Lines

In manufacturing, industrial conveyor systems are key. They help move materials smoothly along assembly lines. This makes work flow better and faster.

They also cut down on manual work. This makes production faster and more efficient. It shows how important they are in factories.

Warehousing and Distribution Centers

In warehousing and distribution centers, conveyor systems are essential. They help move goods from one place to another. This makes getting and sorting items quicker.

Being fast and accurate is key. It makes customers happier. It also means fewer mistakes from handling things by hand.

Food and Beverage Industry

The food and beverage industry needs conveyor systems for safe and clean transport. These systems follow strict health rules. They make sure products are handled right from start to finish.

Keeping things moving while keeping them clean is vital. It’s why these systems are so important.

| Industry | Key Functions | Benefits |

| Manufacturing | Material movement along assembly lines | Increased efficiency, reduced labor costs |

| Warehousing | Goods transport from receiving to shipping | Faster operations, fewer errors |

| Food and Beverage | Product handling in a sanitary manner | Compliance with safety standards, improved hygiene |

Automated Conveyor Solutions

In today’s world, automated conveyor solutions have changed how businesses work. They make things run smoother and faster. This helps a lot in getting things done without delays.

Enhancing Productivity through Automation

Automated conveyors make things better by cutting down on human mistakes. They use smart tech to adjust as needed. This means they can handle materials more efficiently.

For example, sensors can change the speed of belts based on what’s needed. This keeps things moving without any hiccups. It’s a big help in places like Malaysia, where competition is high.

Examples of Automated Conveyor Systems

There are many automated conveyor systems out there. They show how good automation can be for handling materials. Here are a few examples:

- Smart conveyor belts that adjust speed for better flow.

- Automated sorting systems that sort packages by size for more accurate packing.

- Robotic arms that can pick, place, and pack items on their own.

These examples show how automated conveyors can boost productivity. They help businesses succeed in a world that’s getting more automated.

Important Factors in Conveyor System Design

Designing an effective conveyor system needs careful thought. Two main factors to consider in a conveyor design are load capacity and space planning. Both are crucial for the system’s efficiency and function.

Load Capacity Considerations

Figuring out the load capacity is key. It determines the strength and durability of the conveyor parts. The weight and density of the materials being moved affect the design.

Choosing the right materials for belts, frames, and rollers is important. They must handle the load without breaking down too soon. A good load capacity also ensures safety and meets regulations.

Space and Layout Planning

Planning the space and layout is vital for a conveyor system’s success. A well-planned layout improves flow and uses space well, especially in tight areas.

Thinking about vertical and horizontal angles helps avoid bottlenecks. It also makes the workflow smoother. Identifying where to connect with other systems helps make everything work together better.

Choosing the Right Conveyor Manufacturer

Finding a good conveyor manufacturer is key to making your system work better. Knowing what to look for makes choosing easier. It’s important to check if the manufacturer fits your business needs well.

Key Qualities to Look For

When searching for a reliable conveyor maker, consider these points:

- Industry Experience: A seasoned manufacturer knows the challenges of various industries.

- Product Range: A wide range of products means they can meet your specific needs.

- Customization Capabilities: Tailored solutions improve efficiency and fit your unique setup.

- Quality Assurance: Choose makers who follow quality standards for durable products.

- Customer Support: Good after-sales service helps with any problems and keeps systems running smoothly.

H3: Comparing Conveyor Solutions

When looking at different conveyor options, think about these important factors:

| Factor | Manufacturer A | Manufacturer B | Manufacturer C |

| Cost | RM 10,000 | RM 12,000 | RM 11,500 |

| Lead Time | 4 Weeks | 6 Weeks | 5 Weeks |

| After-Sales Service | Excellent | Good | Average |

By looking at these factors, you can pick the best manufacturer. This leads to better conveyor systems that boost productivity and last longer.

Future Trends in Conveyor Systems

As industries grow, it’s key to know about future trends in conveyor systems. Smart technologies are changing how things work. They make operations better, maintenance easier, and cut down on downtime.

Integration with Smart Technologies

Smart tech is crucial for today’s conveyor systems. The Internet of Things (IoT) lets manufacturers watch how their systems perform live. This means they can fix problems before they happen.

Smart sensors and data help make conveyor systems smarter. This boosts safety and productivity. It’s important for companies to use these new technologies to keep up.

Sustainability in Conveyor Design

More people are focusing on making conveyor systems better for the environment. Using energy-saving parts and recyclable materials is key. Companies are working to use less energy and move materials better.

As things change, businesses that care about the planet will do better. They’ll also work more efficiently.

| Trend | Description | Benefits |

| Smart Technologies | Incorporation of IoT and data analytics | Improved monitoring, predictive maintenance |

| Sustainability | Energy-efficient components, recyclable materials | Reduced environmental impact, cost savings |

| Automation | Increased reliance on automated systems | Enhanced productivity and reduced labor costs |

By understanding and using these trends, businesses can stay ahead. Smart tech and caring for the planet will shape the future of conveyor systems. This will lead to new ideas and better ways of working.

Conclusion

Conveyor systems are key in many industries, making things more efficient and saving on labor costs. They help move materials smoothly and keep up with the latest in manufacturing and distribution. As Malaysia’s industries aim to be more productive, using good conveyor systems is crucial.

It’s also important to keep up with new trends in conveyor technology. This helps businesses grow and stay innovative. By investing in the latest conveyor solutions, companies can meet their needs and stay competitive.

Understanding the value of conveyor systems helps companies improve their operations. They can find new chances in the market and ensure success in different fields.