Industrial Supplies in Malaysia: Comprehensive Guide for Businesses

11/03/2025Industrial Automation Solutions in Malaysia: The Future of Manufacturing

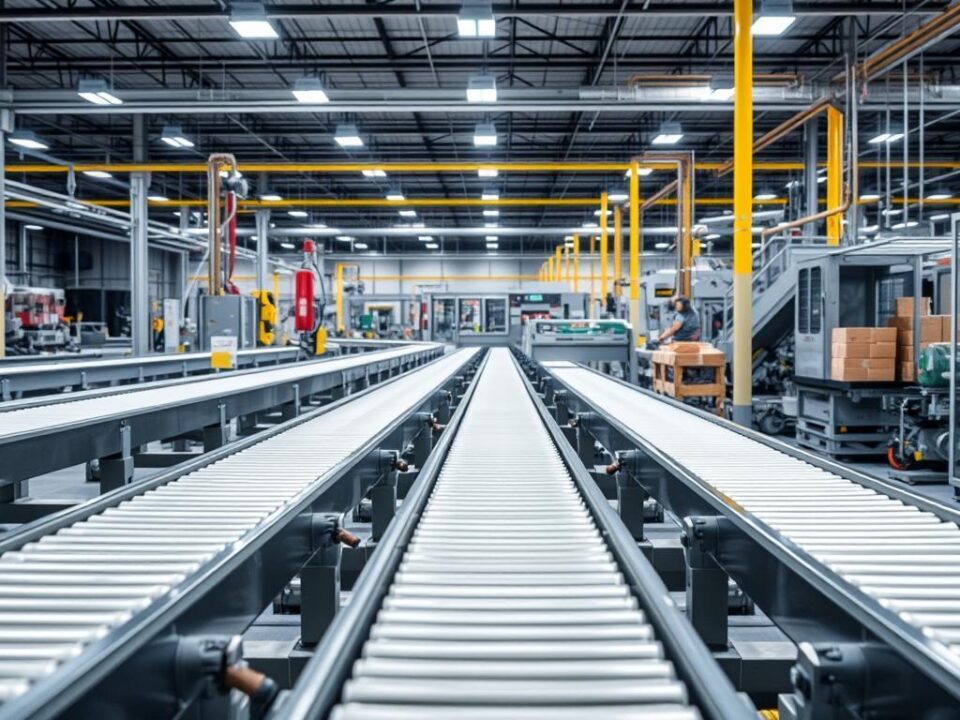

In the fast-changing world of manufacturing, industrial automation in Malaysia is key. It boosts efficiency and productivity. Businesses are looking to improve their operations, and automation solutions in Malaysia offer new ways to do this.

This change makes processes smoother and lets companies use the latest technologies to be ready to lead in using smart factory solutions and robotic automation.

Key Takeaways

- Industrial automation enhances efficiency and productivity in manufacturing.

- Automation solutions are integral to modern industrial practices in Malaysia.

- Robotic automation is a key trend shaping the future of manufacturing.

- Smart factory solutions are essential for innovation in production processes.

- Malaysia is positioned as a leader in adopting advanced automation technologies.

Introduction to Industrial Automation

Industrial automation uses control systems to run equipment in factories. It’s key to making processes more efficient and accurate. By using automation, factories can work better and make fewer mistakes.

At the heart of industrial automation are industrial control systems. These systems manage factory equipment and processes. They allow for quick changes and monitoring. Technologies like programmable logic controllers (PLC) are essential. PLC programming helps machines work exactly as planned.

When automation is added to factories, things change for the better. It makes production faster and safer. In today’s fast-paced world, companies use these advanced technologies to stay ahead.

Importance of Automation in Manufacturing

Automation is key in manufacturing. As industries grow, using automation is crucial to stay ahead. It makes processes faster and cuts down on labor costs.

Automation also boosts quality control. Robots and automated systems reduce errors, keeping product quality high. This lets businesses quickly meet changing market needs, keeping operations efficient and quality high.

Automation makes work better for employees. They can do more creative and problem-solving tasks. Machines handle the routine work, making jobs more satisfying and creating a healthier work place.

Companies that use automation are seen as leaders. They can handle challenges and opportunities better, keeping growth and profits up. Investing in automation is not just good; it’s necessary for success in manufacturing. As a leading industrial automation solution provider in Malaysia, we specialize in such services to help business across the country.

Key Industrial Automation Solutions in Malaysia

Industrial automation in Malaysia uses new technologies to make things more efficient and productive. It includes many solutions that are key in sectors like cars and electronics. Systems often integrate precision components such as gear motors or electric motors for seamless operation. These tools help companies work better and faster.

Automation Solutions Overview

Robotic automation in Malaysia is very important. It uses robots for tasks that need to be done over and over. This lets people do more complex jobs. Other big solutions include smart manufacturing systems and IoT technology.

These systems help companies make better choices by analyzing data in real time. This is thanks to IoT technology.

Benefits to Manufacturers

Using these automation solutions has many benefits for manufacturers. Some of the main advantages are:

- Operations run faster with less downtime.

- It costs less to run the factory because you need fewer people.

- Quality stays high because everything is done the same way.

- Companies can make better choices with the data they collect.

Companies in Malaysia are seeing big changes. For example, car makers are making their assembly lines work better with automation. This means they can make more cars without losing quality. It shows how automation can help businesses grow and stay strong.

| Automation Solution | Industry Application | Key Benefits |

| Robotic Automation | Automotive | Improved cycle times, lower labor costs |

| Smart Factory Solutions | Electronics | Real-time monitoring, enhanced decision-making |

| Integrated Manufacturing Systems | Pharmaceuticals | Consistency, improved quality control |

Industrial Automation Malaysia: Trends and Innovations

The world of industrial automation is changing fast. New technologies like the Internet of Things (IoT), artificial intelligence (AI), and machine learning are leading the way. These advancements make production better, improve quality, and cut costs.

Government policies help drive these changes. Working together, industries and schools push for new ideas. This keeps Malaysia up to date with the latest in automation. Using smart tech is key for businesses to stay ahead.

- Predictive maintenance using AI to spot problems before they happen, reducing downtime.

- Advanced data analysis for instant updates on production, helping make quick and smart choices.

- Robotic automation for better accuracy and safety in making things, helping humans with tough tasks.

Looking into these new developments shows how they boost work and competitiveness. By embracing these changes, Malaysian businesses stand out worldwide. It’s crucial to keep up with trends that shape automation.

| Trend | Description | Impact on Manufacturing |

| IoT Integration | Connecting machines and sensors for real-time data exchange. | Increased efficiency through optimized resource management. |

| AI and Machine Learning | Utilizing algorithms for smarter decision-making in processes. | Improved quality control and reduced operational costs. |

| Robotics in Manufacturing | Employing robotic systems for precision tasks. | Enhanced safety and productivity in manufacturing environments. |

Robotic Process Automation and Its Impact

Robotic process automation (RPA) is a big step forward in manufacturing. It uses software robots to do tasks that follow rules. This lets companies use their resources better.

Knowing about RPA means seeing how it fits into current systems. This is key for using it well in different fields.

Understanding Robotic Process Automation

Robotic technology has a big effect, mainly because it makes things work better. RPA helps companies do tasks like data entry and order processing faster. This means less mistakes and more work done.

Businesses can then spend more time on important tasks. This makes the workplace more creative and innovative.

Case Studies in Malaysian Industries

Many examples show how RPA works well in Malaysia, especially in electronics, pharmaceuticals, and food. For example, an electronics company made its order system 50% faster with RPA. This saved a lot of time.

In the pharmaceutical world, RPA helped with reports, making them faster and safer. A food company also used RPA to check quality better. This cut down on waste and made products more consistent.

The Role of Smart Factory Solutions

Smart factory solutions are changing the game in manufacturing. They are key to embracing industry 4.0. These technologies connect automated systems and process data in real-time.

Smart factories use advanced tech like artificial intelligence and the Internet of Things. They make operations more efficient and help make better decisions. The main benefits include:

- Automation of routine tasks

- Real-time monitoring and data analysis

- Interconnected systems that facilitate communication

- Predictive maintenance capabilities

In Malaysia, adopting smart factory solutions boosts productivity. It also helps companies keep up with industry 4.0’s fast pace. This is vital for staying competitive in a market that wants new ideas.

By using smart factories, manufacturers make their businesses smarter and more flexible. This change helps the Malaysian manufacturing sector grow. It becomes more resilient and ready to adapt to market changes while using resources well.

| Feature | Description | Benefits |

| Automation | Reduction of manual intervention in production processes | Increased efficiency and reduced errors |

| Real-Time Data Analysis | Continuous monitoring of production metrics | Quick decision-making and improved response times |

| Integration of AI | Utilization of machine learning for process improvement | Enhanced predictive capabilities and operational adjustments |

| Connected Systems | Interoperability among different machines and devices | Smoother operations and enhanced communication |

Choosing the Right Industrial Automation Company

Finding the right industrial automation company is key to a factory’s success. Look at their experience, tech skills, customer support, and past work. It’s important to match the factory’s goals with the automation company’s expertise. This partnership helps improve operations and meets long-term goals. At ADKSB Engineering, we deliver end-to-end factory automation solutions tailored to Malaysian industries.

Factors to Consider When Selecting a Partner

- Experience: Check the company’s history and success with similar projects.

- Technological Capabilities: See if they use the latest automation tech to boost productivity.

- Customer Support: Look at the support they offer, like training and maintenance after setup.

- Past Project Success: Read case studies and client feedback to see their success.

- Alignment of Goals: Make sure they understand your factory’s unique needs and can create solutions for them.

Conclusion

The world of industrial automation in Malaysia is changing fast. These solutions are key to making manufacturing better and more competitive. The future looks bright, with new ways to make things more efficient and cheaper, without losing quality.

As local businesses use these new technologies, they get better at what they do. They also help Malaysia stand out in the world of making things. This is good for everyone involved.

It’s important for businesses to keep up with the latest in industrial automation. Using things like robots and smart factories helps them succeed for a long time. This is good for the company and for Malaysia’s economy too.

By focusing on automation, companies can make their manufacturing better and more competitive. This helps them do well in the changing world of trade and industry. It shows how important it is to keep up with new ideas.